Pilot Bushing

AMC Engine

to

Jeep T150 or T18 Transmission

A precisely sized pilot bushing is essential to proper manual transmission installation. We generally recommend a bronze bushing for Jeep applications (when available) as they seem to better endure the harsh environment of a clutch housing. However, with proper installation a needle roller bearing is acceptable, so long as the transmission input shaft hardness is up to the hardness of the needle bearing.

Product & Features

Novak pilot bushings are made from quality Oilite bronze alloy, or in the case of a bearing, a quality needle roller assembly. Often, in adapted applications, a custom outer diameter, inner diameter or even a pressed in sleeve are used to meet the needs of that particular application.

Applications & Compatibility

Transmission

Early 1972-1975 Jeep T18 Transmissions used a ~3/4” pilot diameter. Later 1976-1979 Jeep T18 and T150 Transmissions used ~17mm pilot diameter. It is always safest to measure the pilot tip diameter to be sure. The 76-79 T150 has a very long pilot tip. If the end is damaged or someone has cut it off at some point, you can use the same Pilot Bushing as a Ford in the rear bore of the crank. This also applies to the Jeep T18 kits that have been retrofitted with our T18-ISK described here and available below.

Later 4.0L Cranks

Jeep/Mopar 4.0L engines from 1992-2006 typically (but not always) have a 1" inner crank bore, whereas the previous 4.0L and 258 cranks feature a ~1-1/16" crank bore. We have had customers who felt certain of the vintage of their engine (or its crank, in the case of remanufactured long-blocks or custom builds) only to find their pilot bushing bore to be a different diameter than expected. We recommend you measure your crank bore prior to ordering, to be sure of the correct pilot bushing choice.

Early AMC Cranks

Not all AMC crank flange bores are the same. Early engines, 1971 and previous - as well as those with automatic transmissions around this era - featured a ~1.8" step (see image to the right) or a shallow recess instead of a ~1.8" centering bore as found on later AMC V8 engines. This distinction is important to make if adapting to a transmission where the pilot bushing is positioned further rearward due to a shorter input shaft length. All early and late cranks (in our documentation) feature a pilot bushing bore (the deeper bore in the crank) that is just over 1" in diameter whether they have the above step-bore, or not. On the later engines you are placing the pilot bushing where an automatic transmission would normally index the torque converter. Also be aware that on AMC engines originally equipped with a TH400 automatic transmission there may be a thin centering ring that will need to be removed to install the larger pilot bushing. If the bore measure ~1.7” instead of the expected ~1.8” you’ve got the bushing that needs to be removed. That ring 5352374 is located here.

Not all AMC crank flange bores are the same. Early engines, 1971 and previous - as well as those with automatic transmissions around this era - featured a ~1.8" step (see image to the right) or a shallow recess instead of a ~1.8" centering bore as found on later AMC V8 engines. This distinction is important to make if adapting to a transmission where the pilot bushing is positioned further rearward due to a shorter input shaft length. All early and late cranks (in our documentation) feature a pilot bushing bore (the deeper bore in the crank) that is just over 1" in diameter whether they have the above step-bore, or not. On the later engines you are placing the pilot bushing where an automatic transmission would normally index the torque converter. Also be aware that on AMC engines originally equipped with a TH400 automatic transmission there may be a thin centering ring that will need to be removed to install the larger pilot bushing. If the bore measure ~1.7” instead of the expected ~1.8” you’ve got the bushing that needs to be removed. That ring 5352374 is located here.

Related Products

You may want to order additional bushings if you are unsure of your installation abilities or diameter of the crank.

Installation Requirements

Removal of the old bushing and cleaning the crank bore is required prior to installation. There are a number of official and unofficial methods out there to remove the old bushing/bearing. Hydraulic removal using inserted grease behind the bushing (or wet paper towel, etc. and a precisely sized rod is a classic. Our preferred method is a slide puller available from your local parts store as a rental tool if you don’t own one.

Removal of the old bushing and cleaning the crank bore is required prior to installation. There are a number of official and unofficial methods out there to remove the old bushing/bearing. Hydraulic removal using inserted grease behind the bushing (or wet paper towel, etc. and a precisely sized rod is a classic. Our preferred method is a slide puller available from your local parts store as a rental tool if you don’t own one.

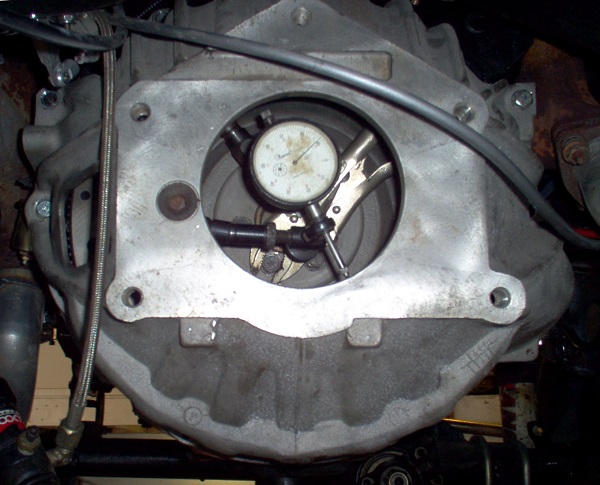

A proper drift tool or driver is recommended for installation. Do not coat oiled bronze in grease, as this plugs its pores and will not lubricate properly afterwards. Installation as the bushing comes is acceptable, though soaking it for a day or longer in clean engine oil prior to installation is preferred. Freezing the bushing and lightly warming the crank can ease the installation. Pilot bushing and transmission input and main shaft damage are inevitable if the bellhousing and transmission are not centered concentric and parallel to the engine face. We recommend the use of a dial indicator to verify that your bellhousing and engine are centered on the bellhousing bore. See The Novak Guide to Clutches, Linkages and Bellhousings for directions on this method.